There are many 3D metal printers available on the market, so deciding which machine is right for your business can be challenging. Reading through endless lists of specs and features can be mindboggling! So, rather than getting lost trying to compare printers, it might be better to ask questions about your use cases. This can then help you to narrow down the right printer for your specific needs – and avoid purchasing hardware that doesn’t really help you.

Most companies who need a 3D metal printer for industrial purposes opt for Selective Laser Melting (SLM) machines, or Direct Melting Laser Sintering (DMLS) which work in similar ways. Although, these kinds of 3D printers are the most expensive ones, expecting to pay about EUR 500,000 ($ 600,000) up to around EUR 2 million ($ 2.4 million), we’ve assumed you are on the market for this kind of machines. The following five questions shall therefore help you to narrow down your choice of your optimal 3D metal printer.

5 considerations when buying an SLM or DMLS machine

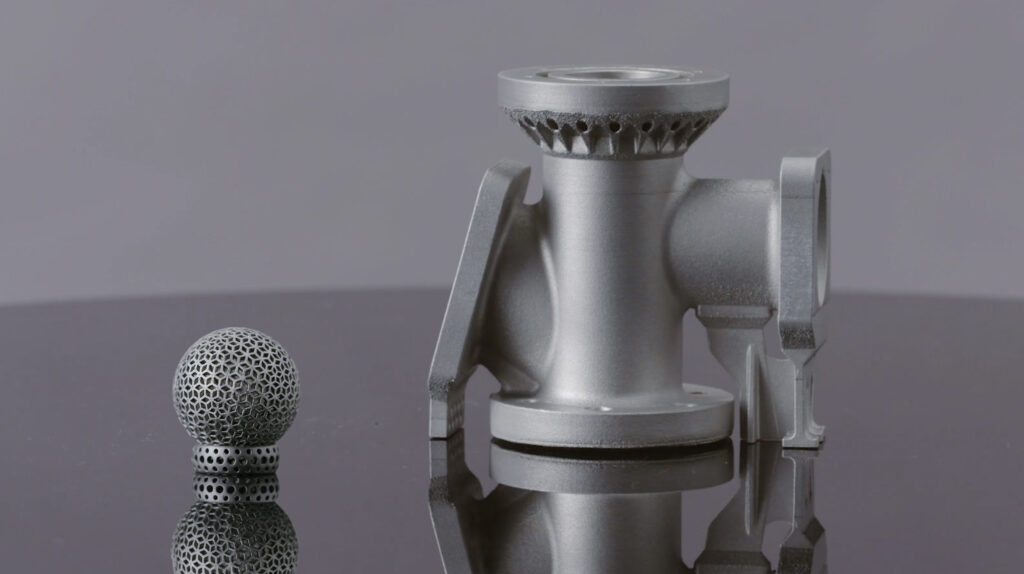

1. What part sizes will you be printing?

Logically enough, the bigger the printing chamber, the larger the parts you can print. Smaller SLM and DMLS printers come with chambers of around 125 mm³. Meanwhile the biggest machine on the market is SLM 600, which has a 600 mm³ printing chamber.

If you’re printing quite small units (such as customised parts for medical implants) a small machine will be perfectly fine. But if you’re printing bigger parts, such as machinery to go inside a wind turbine, you’ll want a bigger chamber.

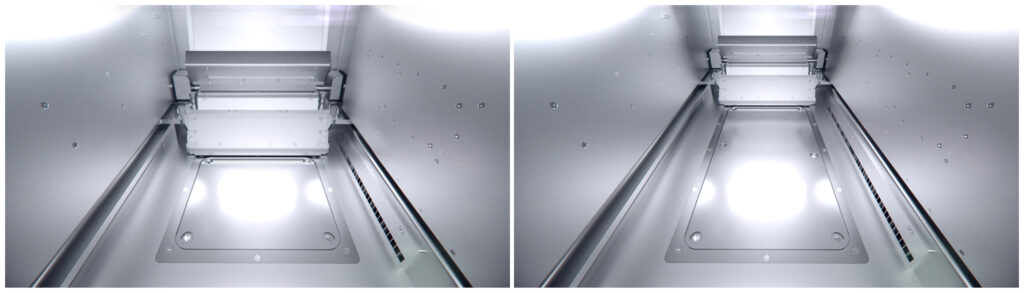

2. How many lasers do you need?

In metal 3D printers, lasers melt metal powder to ‘build’ up a part. Of course, all SLM and DMLS machines come with at least one laser, but they may be fitted with two, four, eight or even twelve. The more lasers you have, the faster the printing. Doubling the number of lasers will (roughly) cut the printing in time by half. Each additional laser speeds up the job further. Bear in mind that lasers cost a lot – each additional laser will add around EUR 80,000 to your machine.

3. Is the goal prototyping or serial production?

Do you plan to use your printer mainly for prototyping of one-off parts and experimentation? In this case, a smaller printer will do the job just fine.

On the other hand, if you plan to print multiple parts at once, it makes more financial sense to purchase a machine with a larger chamber which will let you produce several units in each batch.

4. How much energy will you be using?

3D metal printers are both time and energy intensive. Keeping them running will therefore significantly increase your energy bills. Smaller machines use less energy, so they’re better suited to occasional prototyping. If you were to use a large machine for this purpose, it would require far more energy for the same size job.

But, if you’ll be using the printer often for multiple printing jobs, it’s much more economical to use a big printer that can produce multiple parts per run.

5. How fast do you need to print?

Different 3D printers are able to melt layers of metal at different speeds. For example, one printer might take one second to melt a single layer of metal powder, another printer might take two seconds to do the same thing. This might not seem a huge difference to begin with, but if the job involves melting 50,000 layers of metal, that difference could add a couple of working days to the job.

Faster printers naturally cost more money, so it’s worth considering how quickly you need jobs to be completed. If you’re happy waiting a couple of days for each run, this could save you a lot of money. On the other hand if you’re interested in 3D printing because you want to build rapid prototypes, a faster machine is going to save you a lot of frustration.

What SLM/DMLS printer will you choose?

The five questions above can help you to narrow down your options when it comes to choosing the right 3D metal printer for your needs. Knowing more about how you’ll use it can be very valuable when you go into meetings with 3D printer firms too.

After choosing the printer, your next decision is about the kind of 3D metal printing software you will use to actually design parts and tell the printer what to do. As one of the top providers of editing software for SLM and DMLS printers, CADS Additive can help you find the optional combination of hardware and software for your business’s needs. Contact us today to talk about your 3D printing strategy,